From your phone to space rockets, the items made of ceramics are numerous. If I say we live in a ceramic world, it would not be an exaggeration. But how are ceramics made? Have you ever wondered? Manufacturers use different kinds of clay to make various ceramics. The process is almost the same for all ceramics. First, the clay is made flexible with water and some other chemicals. Then they are given the desired shape. The next step is to bake the clay at a high temperature. The final phase of making ceramics involves glazing and reheating them. In this article, I have elaborately discussed what ceramics is. By reading this article, you will also learn about the process of making ceramics. Moreover, I have elaborated on the use of ceramics in our lives in the latter part of the article.

What Is Ceramic?

There is no single material that you can call ceramic. You can say it is a group of artificial materials that are hard, heat-resistant, brittle, and corrosion-resistant. Ceramics are made by firing some inorganic, nonmetallic elements like clay. Some common examples of ceramics are porcelain, bricks, and earthenware.

History Of Ceramics

The first use of ceramics in human history was at least 26,000 years ago. Archeologists found some ceramic-made sculptures in southern central Europe from that age. Researchers believe people of that age mixed animal body parts with clay and baked them in high temperatures to make the first kinds of ceramics. Historians say people started using ceramic in daily utensils around nine thousand years ago. At that time, a particular population in Europe was known for using ceramics. They are now called the Corded Ware culture. However, people of that age baked potteries with wet ropes wrapped around them. The marks of the rope gave decorative patterns to the ceramic potteries.

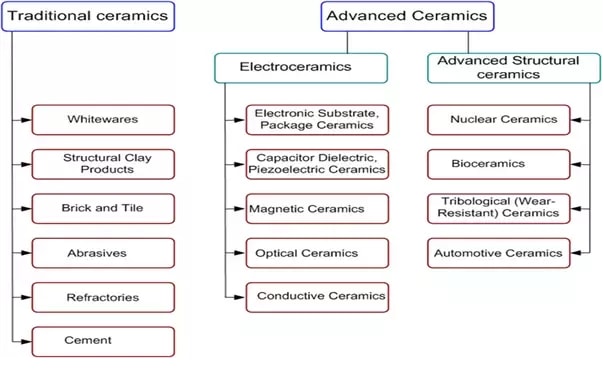

Types of Ceramics

There are mainly two kinds of ceramics. Traditional ceramics and advanced ceramics. Researchers used advanced engineering technologies to create engineered ceramics. • Traditional Ceramics: Manufacturers use plain clay and silica to make traditional ceramics. An example of typical ceramics is the toilets in your restrooms. All the bricks, glasses, tiles, porcelain, and concrete are also examples of traditional ceramics. • Advanced Ceramics: Since the early 20th century, we have seen ceramics with advanced engineering. However, researchers created most of them for particular purposes. They invented silicon nitrides for making cutting tools. On the other hand, manufacturers use silicon oxide ceramic to make microchips. To make space ships, humans developed lithium-silicon oxide ceramic.

Common Characteristics of Ceramics

To understand why ceramics are in such high demand, you need to know about the common characteristics that every ceramic material has in it. • Heat-Resistant: Every ceramic item goes through a baking process, and every one of them is heat-resistant. However, these ceramics will only melt at a high temperature. • Toughness: Invariably, every ceramic element is hard and strong, since the concept of ceramic is high durability. So, it is not ceramic if it is not strong and durable enough. • High Insulation: All the ceramic items transmit very little electricity or temperature. This long-conductivity feature makes the ceramics good insulators. • Chemical inertness: Another attribute of ceramic materials is their indifference to different chemicals. All the ceramics generally do not react to any chemicals in a given condition.

How are Ceramics Made?

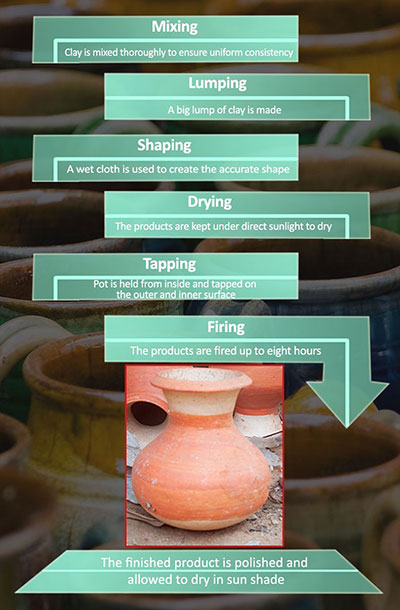

In general, you can make ceramics by burning certain clays at high temperatures. The process of making ceramics involves four phases. Here I have elaborated on the whole process of making ceramics.

Collection of Clays

Manufacturers collect the clay to make ceramics by excavating the earth. Ceramics, on the other hand, cannot be made with just any clay. The clay must have silicon and sand mixed with it. That clay can be found deep beneath the surface in certain geographical areas. Manufacturers excavate this clay from quarries.

Making the Clay Flexible

The next phase of creating ceramics involves making the clay soft enough to give it any desired form. To do that, manufacturers use water and some other chemical agents.

Giving the Clay Proper Form

Now that the clay is flexible, it is high time to give it a shape that is useful for any particular purpose. If you are making pottery with ceramic, you need to shape the clay just like the final product. If you want to use ceramics for industrial purposes, you need to make clay shapes using machines.

Baking the Clay

At this stage of making ceramics, the clay is baked at a high temperature to harden it into a permanent shape. When you heat the clay at 1500 °C, it takes an irreversible form thanks to a series of chemical reactions.

Glazing the Ceramic

Finally, the ceramic is glazed and heated. By glazing, the material manufacturers make them non-porous or water-resistant.

What Clay Is Used To Make Ceramic?

Not all clay is suitable to become ceramics. The clay must have a certain amount of sand or silica in it. Here is a list of some of the clays you can use to make ceramics. • Ordinary Clay: This clay is available in abundance in nature. You do not need to excavate them from a quarry. From this clay, you can produce ceramics like bricks, aggregates, and cement. • White Clay: Manufacturers use white clay or Kaolinite to make those ceramics needed to make porcelain, kaolin, glossy papers, and morphine- a widely used medicine. • Bentonite Clay: You need this clay to make ceramic used in producing drilling mud, foundry sand, and other household products. • Ball clay: Ball clay has high demand in the market. Manufacturers use them to produce sanitary ware and all kinds of wall and floor tiles. • Fire clay: You can find fire clay only in mines. Manufacturers need this ceramic to produce some heat-resistant products used in metal manufacturing. They use fire clay to make ceramic holders for the electric transmitters.

What Are The Best Uses Of Ceramic?

You can find ceramics in almost every object around you. It would be easier to tell which objects around you do not have any ceramic in them. I have listed a few common uses of ceramics. These things would not be in our lives without ceramics.

Modern Houses

Manufacturers use different ceramics to make most of the elements of a modern house. Bricks and cement are two key elements to building a house. It would not be possible to make those elements without using ceramics. Each of these materials uses different kinds of ceramics.

Wall and Floor Tiles

Manufacturers use ceramics to make all kinds of tiles. Researchers used advanced technologies to engineer these ceramics. That is why they are non-porous.

Sanitary Ware

All the sanitary items in your bathroom and all around the house are made of ceramic. Sanitary ware, including the toilet and sink, is made from ceramics of ball sands.

Glass Materials

Can you imagine a world without glasses? Other than the plastic-made ones, all of them are made of ceramics.

Electronic Components

The modern world moves on electronic devices. Manufacturers use ceramics to make all electronic devices. All microchips, capacitors, or resistors in all electronic goods have ceramics in them.

Crockeries

This is one of the ancient uses of ceramics. In the initial stages of civilization, humans started making ceramic potteries. All the porcelain in your house is a pure form of ceramics.

Airplanes

All airplanes have a component called a gas turbine. It burns fuel mixtures to make fiery exhaust. Airplanes get the power to fly with these exhausts. The body of the gas turbine is made of ceramics. Apart from that, many of the components of an airplane engine have ceramics in them.

Space Rockets

The body of a space rocket needs to endure a high temperature. That is why they need ceramic as the main element to build the bodies of the space shuttles.

Construction Tools

You need tools to saw a brick, cut glass, grind concrete, or drill holes in tiles on a construction site. Manufacturers use different ceramics to produce all these tools. Some engineering ceramics like silicon carbide or tungsten help cut ceramic tiles into usable shapes.

Magnets

You need magnets inside electric devices like loudspeakers or headphones to make them work. Manufacturers make these magnets from certain ceramics called ferrite.

Electric Power Transmitter

All the components of an electric power transmitter that may get hot during the transmission have insulating ceramic holders. Electric cooktops are also made from ceramic glass since they can contain heat.

Medical Use

There are different uses for various ceramics in the medical world. The piezoelectric transducers used for ultrasonography have a type of ceramic in them. Presently, doctors use silicon nitride ceramics for bone and tooth transplants. Related Topics Does Silicone Melt Does Brake Fluid Evaporate Natural Gas vs Gasoline Does Propane Go Bad Combustible Vs Flammable Is Gasoline a Homogeneous Mixture Does Sand Absorb Water Do Asteroids Orbit the Sun Do Meteors Orbit the Sun Is Smoke a Colloid

Bottom Line

After reading this article, I believe you are now more aware of the importance of ceramics in our lives. Now you can answer the question- how are ceramics made. I guess your knowledge of ceramics has made you more knowledgeable about the world around you. I hope you will find this article as a complete reference on ceramics.